Hard won energy - working with the material

It bites! Long leather rigger gloves helped protect the wrists with another smaller pair worn underneath to limit most of the more persistent needles. Removing them from your hands and legs was a daily occurrence with some causing infections fairly quickly if not removed. Some were impossible to remove and I’m still finding them now. Handling by the stem was the way. The larger bushes had to be reduced in size by pulling the branch away from the stem. It was cut mainly with machete but also loppers and bow saw.

The first crop of furze cut for the project by the National Trust was at Coverack [the other sites were Kelynack, St Just, Morvah, Gulval, and Tolver]. This presented two problems for me. One I didn’t really know how much material I actually needed. Furze hasn’t been used in a construction for over 30 years that I know of and possibly longer elsewhere. There was no one to tell me how to do it. I had to rely on my skills learnt as a dry stone waller/stone hedger to visually quantify the amount. This also meant I had to take anything that would bundle up into a faggot. I couldn’t afford to leave some behind because it was a bit too twisted or the like. This meant that when I came to carry them by hand some where too heavy to lift. Also as the furze had been cut it had been unceremoniously dumped in large piles and had consequently become tangled up and difficult to separate. In the past the would have been laid out with a thought to how it would be handled next in the faggot making process thus making it more time and cost effective.

Instances like this, when material handling for example, really brings a sense of its historical context to life. You start to get a feeling about how they would have done things - and how they wouldn’t. The next cutting that took place was done in a much more orderly way. Each compartment of cut furze was laid out in lines so that when it came to laying them out for tying it became a quick and efficient practice. The massive volume of material that was eventually needed [3 full silage trailers loaded and pulled by tractor] inspired all kinds of would be solutions to improve on the old technique of bundling into a faggot and tying with twine. Some ideas required compressing an overly large mass of furze with the winch of a Landrover but this just snapped the branches. Another was to use ratchet straps to act in a similar way but this again failed miserably in comparison to a natural fibre twine as the excess of the strap needed to encompass the faggot was too unwieldy once it had come under compression. The most successful way of creating a faggot was to lay a 3m line of twine on the ground. Lay the required amount of furze on top of this, which as a general rule stood about 1.5m off the ground. This part of the process was an adaptation of the traditional method of faggot making. It was necessary to reduce the overall mass of the material to reduce transport and environmental costs. Traditionally the furze was cut in a manageable armful and then tied with a green whip, possibly goat willow, perhaps in a similar style to how a bundle of willow rods are tied. My adaptation meant laying the fuzz outward at both ends to balance the shape to create a more symmetrical faggot. [This change to the dynamics of the traditional faggot was the main concession to the modern age the project made other than that of transportation]. A loop was tied at the end of the twine drawing the other end through. As the faggot tightened at the pull of the twine I placed my boot onto it to help shape and round of the faggot and to compress it further. Creating a tightly formed well shaped faggot was a really satisfying process. The ideal size and weight of the faggot being determined by whether or not it could be carried by one person.

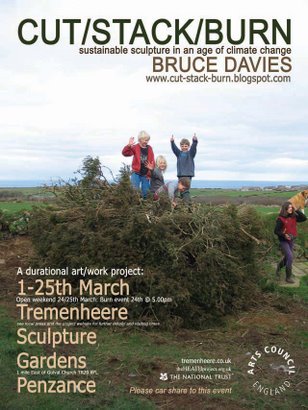

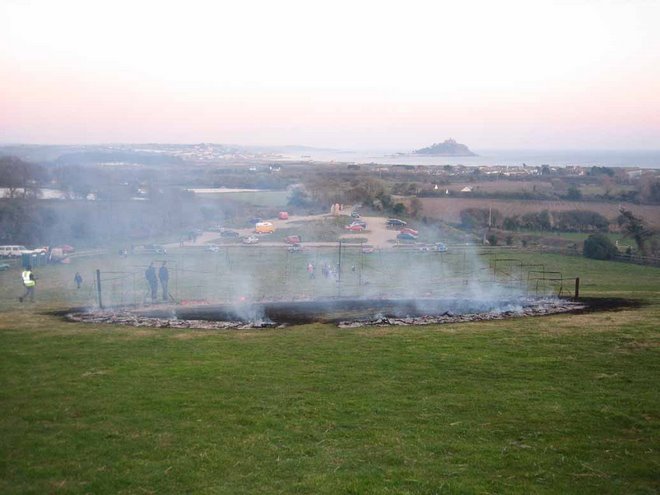

Project outline:CUT/STACK/BURN is a performative re-enactment of a redundant rural activity - furze cutting for domestic fuel (or gorse outside of cornwall). The project uses art installation as a platform to develop a visual conversation about the implications and absence of sustainable approaches in the management of land and its resources. Our current use of energy in an age of climate change becomes a focal point and pivotal issue in this visual debate.

event poster

Sunday, 29 April 2007

Subscribe to:

Post Comments (Atom)

mini beasts

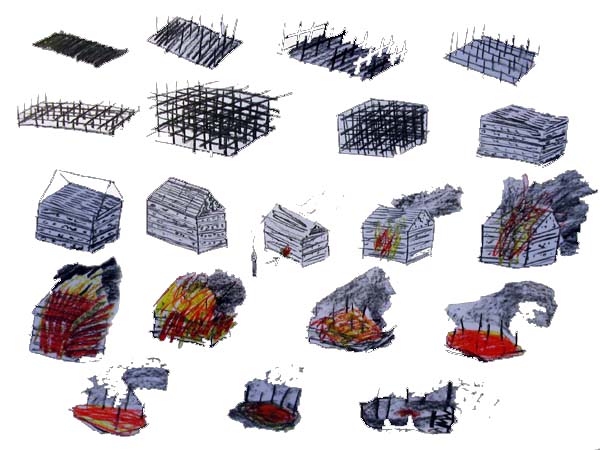

cross section

struts

14

![i survived an assalut by a deadly [natural] weapon and lived to tell the tale](http://photos1.blogger.com/x/blogger2/2561/191242230969139/410/85448/gse_multipart25569.jpg)

No comments:

Post a Comment